Laser Gallery

Since beginning my studies and interests in lasers way back in 1990, I have been fortunate to have collected several lasers and optic related components.

My very first encounter with a laser was from a Marantz CD-34 CD player which used the CDM1 Optical pickup unit, however it was not until December 1990 where I would have my very first Helium-Neon gas laser.

From that moment forward, I have slowly added to my modest collection of lasers which has provided me with invaluable experience and knowledge in the field.

I am very fascinated in seeing the progression of laser technology from the simple and elegant designs to the more "industrious" designs.

I would say I have become somewhat of a collector of lasers, what I do love is seeing some unique pieces which you don't see in modern lasers. I try and keep a lookout for such lasers to add to the collection.

The following is a small sample of the more unique lasers that I have in my collection.

In 2008, I was browsing through ebay and I had come across an interesting and quite a unique laser which I had never seen the likes of before. I placed a bid and successfully secured the laser for my collection.

There is very little to no information or references pertaining to this laser, however, Elliott Electronics Tubes Limited was a British company based in London from February 1961 to July 2002.

This laser would potentially have been manufactured between mid 1960s to early 1970.

The only other known reference to the Elliott 356-HNL-8A laser is at the Science Museum Group in South Kensington, London, with Serial Number. 350.

Description

The Elliott Laser which I have is Serial Number 352, which tells me both these units would have been manufactured within the same year(s).

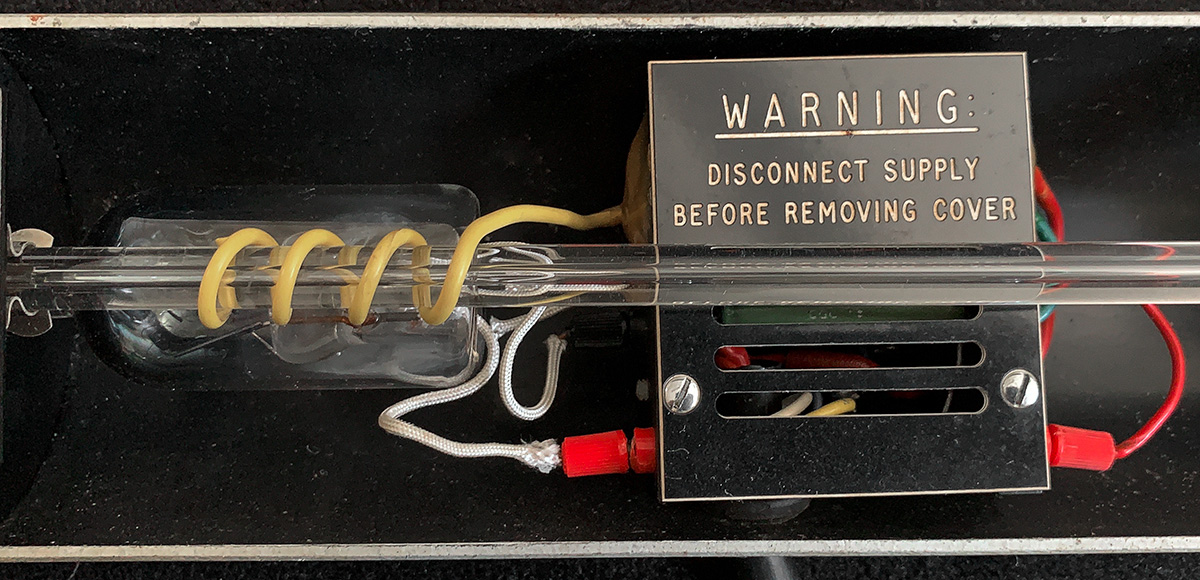

The laser is house on a split-cylinder shaped housing, the bottom half is made of aluminium that forms the backbone support for the endplates and the tube mounting.

The cover is violet coloured acrylic with the embossed logo and high-voltage warning. This is secured using two thumb screws.

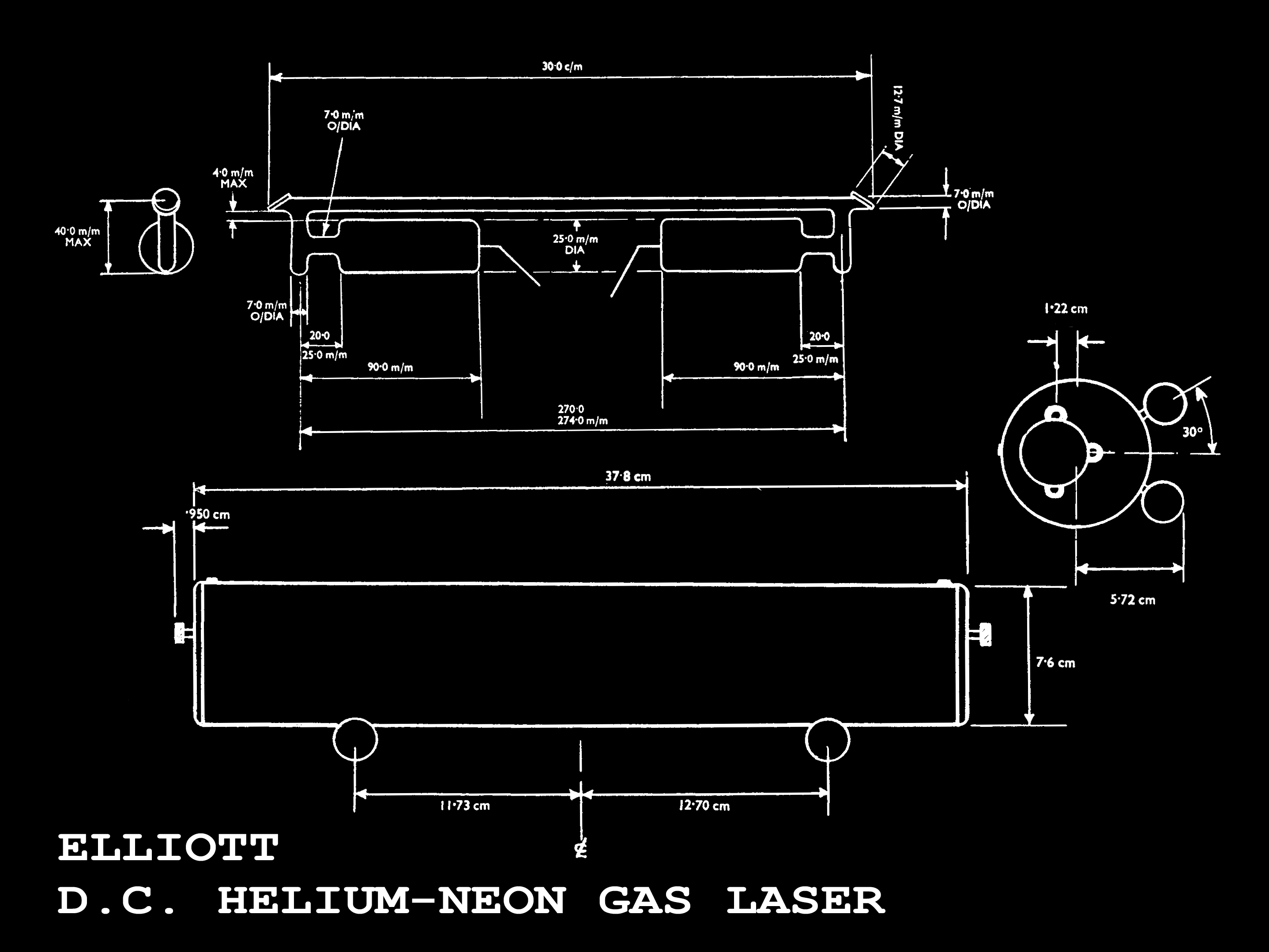

The overall length of the tube between the Brewster Windows is 300mm, with the active region of the discharge being slightly shorter at approximately 240mm. The actual length of the resonator is approximately 340mm which has been determined through measurement as well as the identification of the use of a Plano-Concave mirror set (hemispherical optical resonator configuration).

The internal of the laser is elegant and simple. The yellow wire that is wrapped around the glass discharge bore is to aid in starting the tube. There is a trigger transformer module under the tube where all the electrical connections from the power supply terminate. The starting of the laser would have been very similar in the technique employed with flashlamps, an external triggering pulse.

The tube is of a hot-cathode variety with a filament located in the larger glass chamber. The glass bore is of similar design to modern Helium-Neon tubes, but terminated with Brewster windows, which no doubt are soft-sealed.

Enlarged image showing the (hot) cathode filament

I'm very intrigued by the simplicity and elegant design of the laser especially its optical resonator arrangement.

The end blocks of the laser form a rigid mount where an internal "floating" module is fixed using a screw under spring tension at a single point, this provides a pre-stressed pivot point.

Mirror adjustment is done using the two horizontal thumb screws (two at each end). Individually adjusting one or the other will affect the adjustment in the X-Axis, while adjusting both equally together will affect the adjustment in the Y-Axis.

The mirrors are supported in a removable cell that can be unscrewed from the floating adjustment mechanism assembly. A locking nut is used to lock the mirror cell.

One very interesting observation of the engineering of this laser, is that the distance between the mirrors can be fine-tuned very easily and therefore optimising the optical resonator.

An additional feature of the laser is the use of an intra-cavity adjustable aperture (akin to a camera lens aperture) that allows for selection of the operating laser modes (wide open would produce a multimode output, while closing down would limit the laser to its diffraction limited mode, TEM00). Together with the ability to adjust the resonator length and how much of the active medium is used makes for a very interesting laser which only has been found on high-end scientific grade lasers.

As covered above, the resonator length of the laser is 340mm, this was determined by simple measurement to eye-ball the distance between the mirror surfaces, however, when I re-examined the mirrors, I noted that the HR was not a Plano mirror, but concave.

I proceeded to measure the focal length of the mirror by examining the sharp focus of an image on a card against a ruler, determining the sharp focus at 170mm.

By the relationship that the focal length of a spherical mirror is equal to half the radius of curvature, or f = R2, therefore with a focal length of 170mm results in the curvature of 340mm, matching that of the physical length of the resonator.

Experimentation

In my collection, I had an old Aerotech laser tube, which got the better of me. This tube had an external mirror, that was epoxied onto an extension of the tube that housed the Brewster window. This allowed for the removal of the Output mirror to then conduct some experiments.

One experiment I had performed was to place this tube in the Elliott resonator, where I able to get it lasing.

Legacy Archive:

The following archive are early images when I first acquired the laser.

Elliott Helium-Neon Laser

Updated Information - 9 June 2025

Following some interesting information that has come through on the Elliott Laser, it seems now there are three known units discovered which includes the one we have, S/N: 352. Further Reference has also been found on the Elliott Laser units.

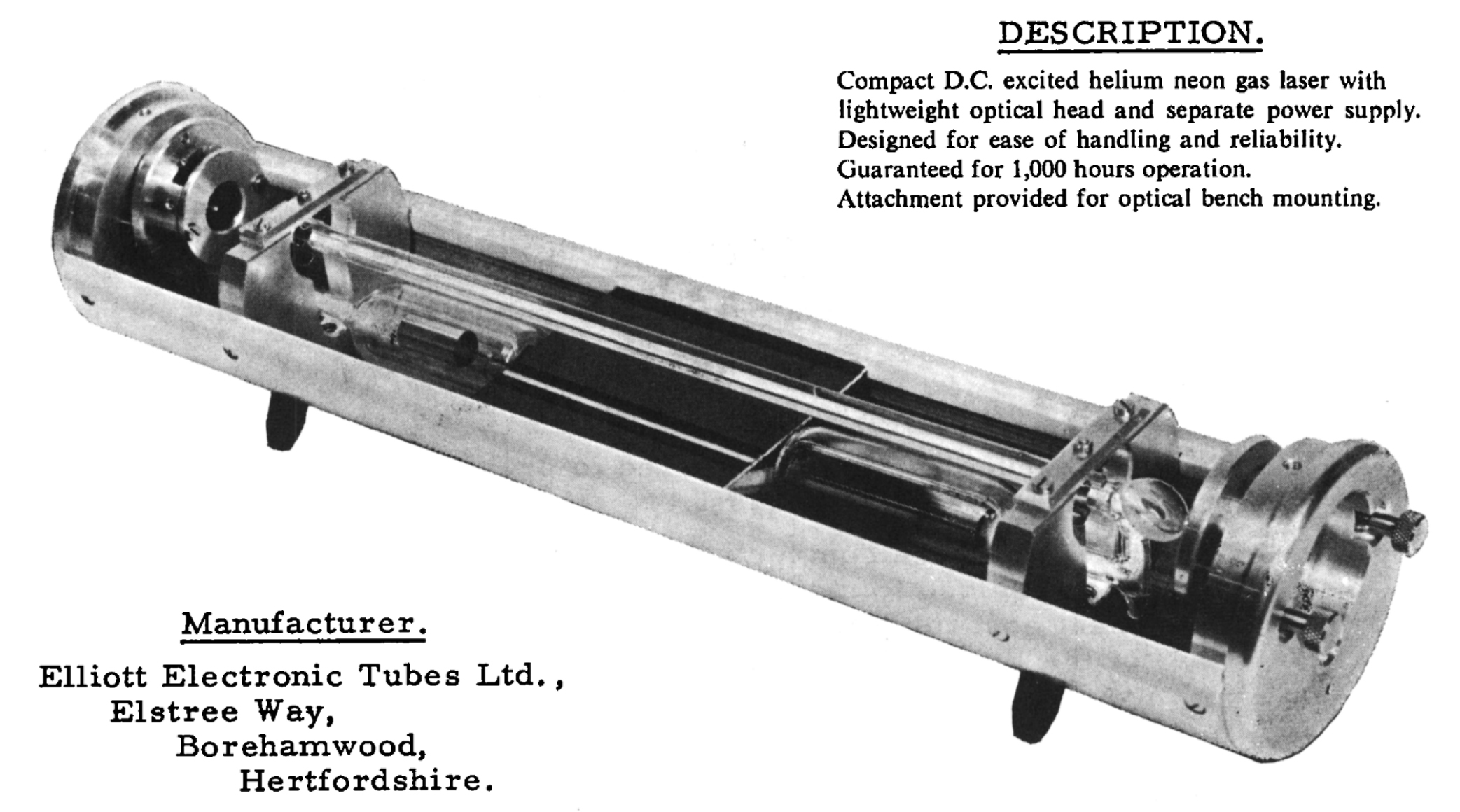

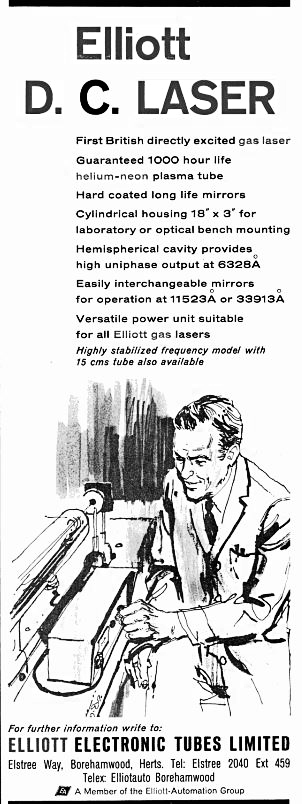

In the following section, we will look at an Elliott Model 315 owned by Dr. Richard Pilkington. The following information obtained from searching the web on the model 315 which does differ very slightly from the newer 356 variant, and some literature has been found (which I have had to pay for).

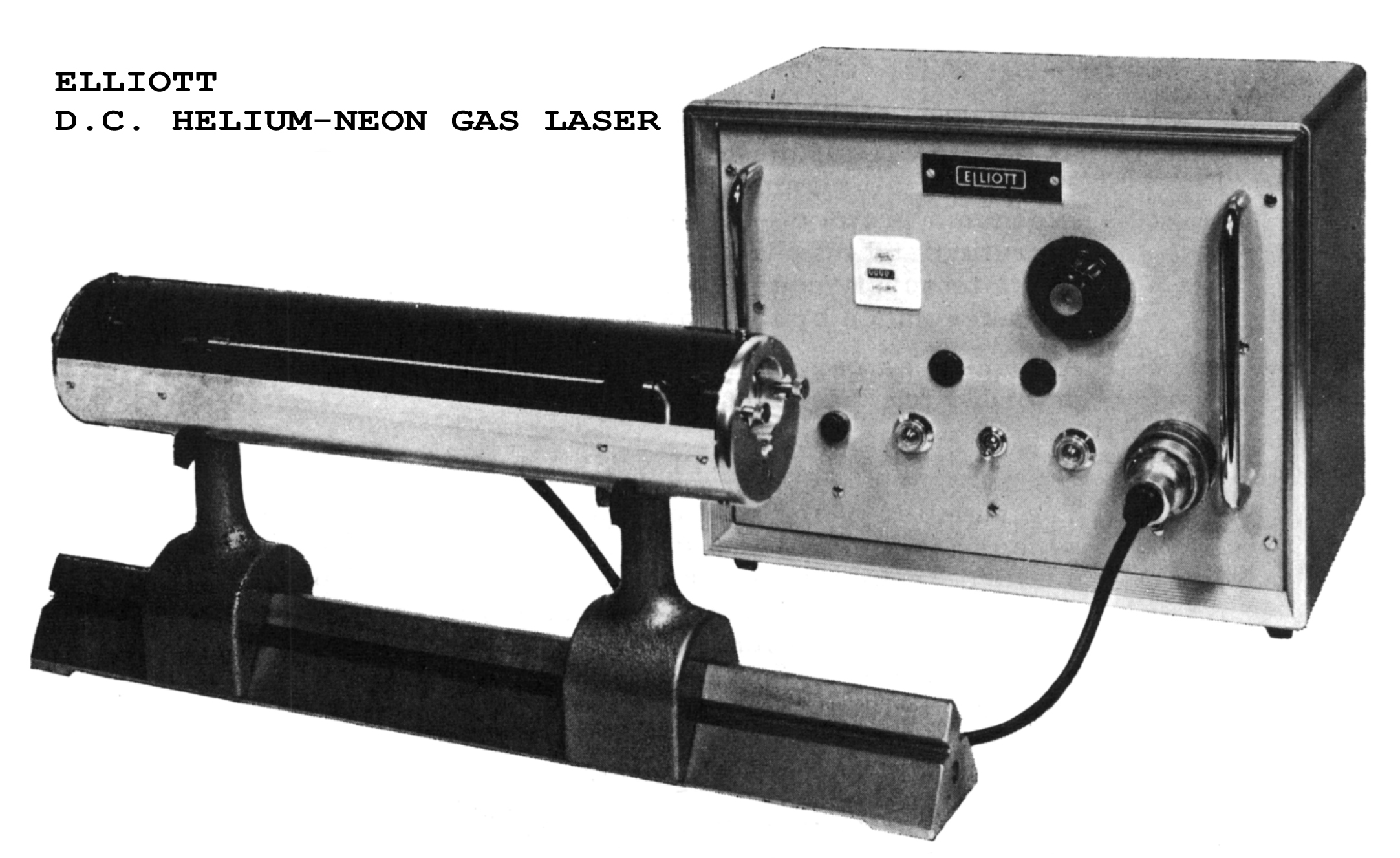

The Elliott Laser unit was designed to be a compact Helium-Neon gas laser system, with a lightweight head and separate power supply unit connected via an umbilical cable. The laser was guaranteed for 1000 hours of operation. The Laser head was provisioned with attachments for mounting to an optical bench.

The plasma tube is manufactured from hard glass (borosilicate) rather than fused silica to reduce helium pressure loss and electrodes designed and mounted off-axis to minimise sputtering of metal on the Brewster windows, increasing service lifetimes.

Optically flat quartz windows are mounted to the tube at Brewster angle to transmit polarised light with minimal loss and contribute to higher gain of the optical resonator.

Dielectric coated mirrors are held in easily adjustable mounts and able to be simply interchanged to allow operation at 1,152.3nm (Infrared) and 3,391.3nm (Far-Infrared).

The mirrors form a hemispherical resonator configuration, comprising of a Plano-Plano mirror and a concave mirror with 350mm radius of curvature, and its outer surface being convex to form a collimation lens.

A thermal delay switch inside the Laser head prevents the high-voltage supply from energising the tube until the heaters have reached operating temperature as well as it being part of the interlock circuit used to energise the high-voltage supply.

The standard hemispherical cavity provides a single transverse mode output (TEM00), however a second spherical mirror can be utilised for the high reflector (HR) to set up a confocal resonator configuration allowing for higher output power with multi-mode output. The built-in aperture diaphragm mounted within the laser cavity is able to be adjusted to finesse the operating transverse modes within the active medium, as well as removing additional 'noise' from the output.

Specifications

- Plasma Tube:

- 300mm x 2mm bore. Hard Glass (borosilicate).

- Windows:

- Optically flat Schlieren-free quartz set at Brewster angle.

- Wavelengths:

- 632.8nm (standard), 1,152.3nm and 3,391.3nm (optional).

- Optical Resonator:

- Hemispherical with collimating output mirror and HR Plano mirror. Confocal mirrors optional.

- Output:

- Hemispherical cavity: 0.5mW minimum at 632.8nm, 7.5mA plasma current, with confocal cavity: 1.0mW minimum at 632.8nm.

- DC Supply Unit:

- Instrument case, 340 x 260 x 200 mm. 0 to 5kV at upto 15mA. Weight: 11Kg.

- Laser Head:

- 40mm x 70.7mm. Weight: 1.3Kg

Catalogue Listings

- 315-HNL8

- D.C. Helium-Neon Laser including 300mm plasma tube in cylindrical case complete with mirrors for operation at 632.8nm and D.C. power supply unit.

- 315-HNL8-06A

- 350mm radius of curvature mirror (OC), 632.8nm dielectric (vacuum evaporated) coatings.

- 315-HNL8-06D

- Plano-Plano mirror (HR), 632.8nm dielectric (vacuum evaporated) coatings.

- 315-HNL8-06B

- 350mm radius of curvature mirror (OC), 1,152.3nm.

- 315-HNL8-06E

- Plano-Plano mirror (HR), 1,152.3nm.

- 315-HNL8-06C

- 350mm radius of curvature mirror (OC), 3,391.3nm.

- 315-HNL8-06F

- Plano-Plano mirror (HR), 3,391.3nm.

- 315-HNL8-03

- 300mm Plasma tube

- 315-HNL8-01

- D.C. Power supply unit with variable output from 0-5kV at upto 15mA compliance.

Credit: Richard Pilkington (UK)

On 8th June 2025, I was contacted by Richard Pilkington, a fellow collector of scientific instruments from his working life in Research Chemistry, Physics and Electrical Engineering.

Richard wrote to me to advise that he had in his collection a similar Elliott laser and appears to be a slightly earlier unit, model No. 315 with Serial number 329.

The model 315 pictured appears not to have the adjustable aperture, and the plasma tube features two larger electrode sections.

Overall, this unit is very similar to the 356.

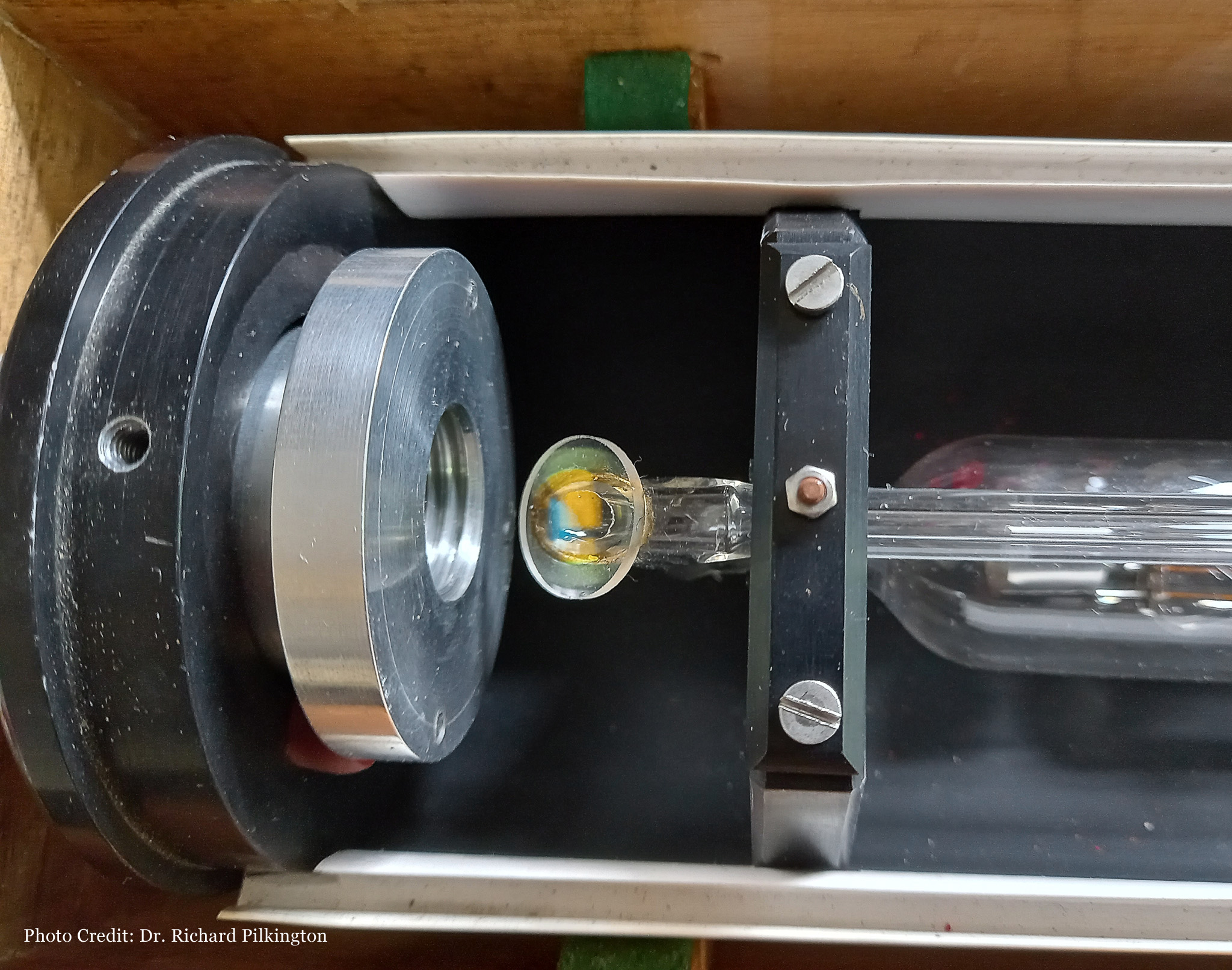

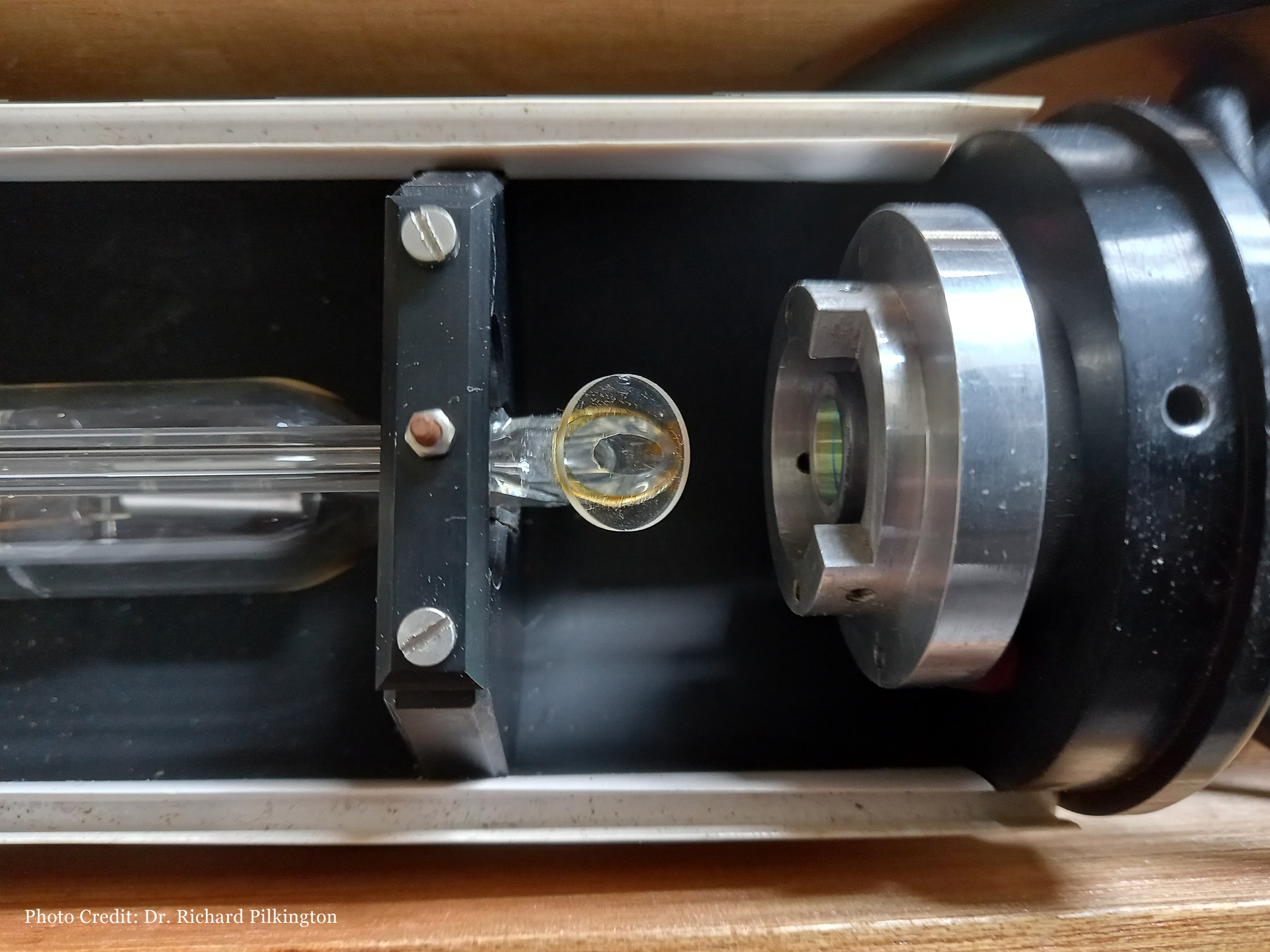

Elliott Model 315-HNL-8A Laser with it's Power Supply

Elliott Model 315-HNL-8A Laser in it's original wooden box

Elliott Model 315-HNL-8A Laser in it's original wooden box

(Cover Removed)

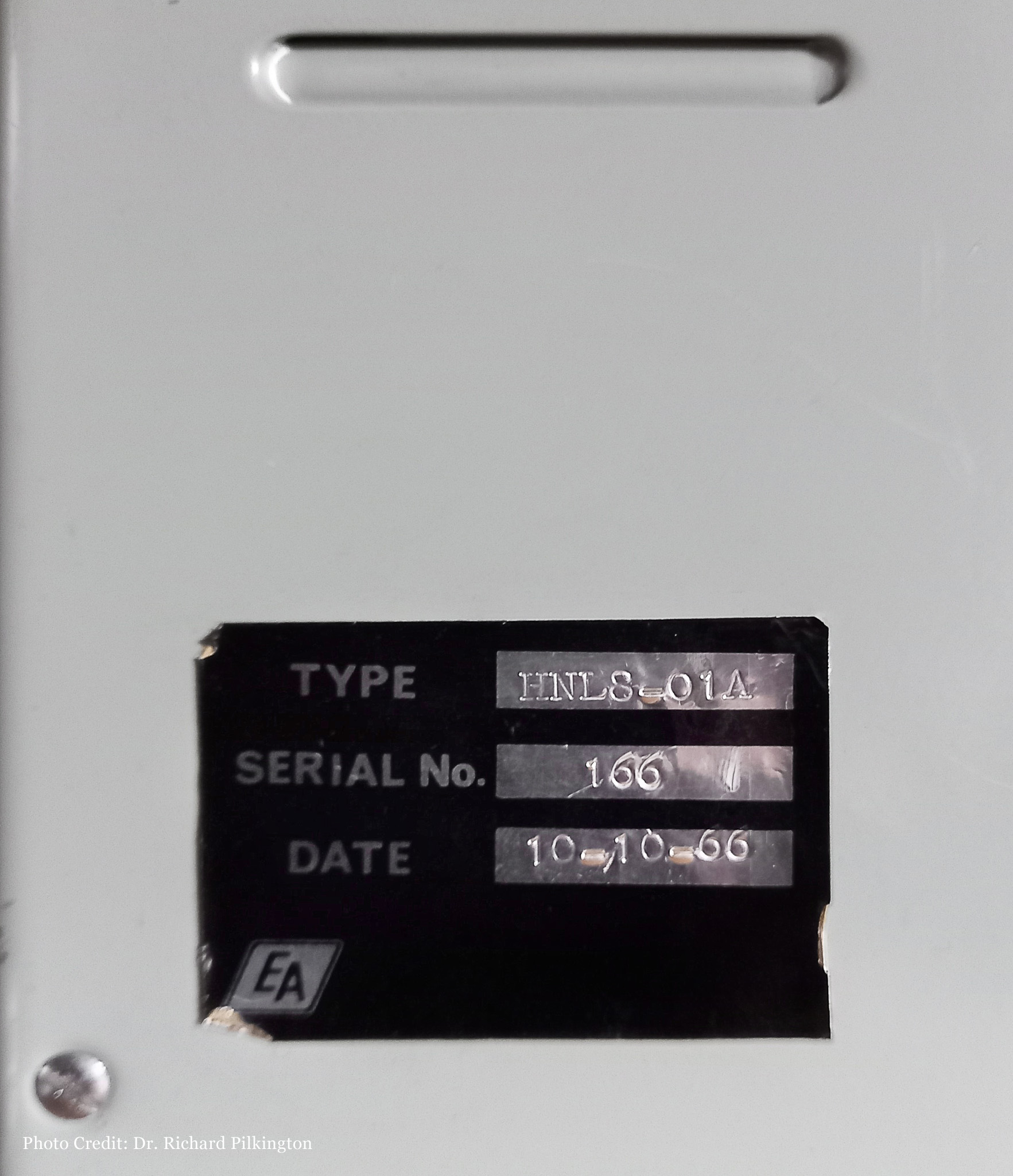

Elliott Model HNLS-01A Laser Power Suppy

S/N: 166, Date: 10/10/1966

Elliott Model HNLS-01A Laser Power Suppy

S/N: 166, Date: 10/10/1966

Much appreciation to Richard for sharing these images with me and providing permission to be able to feature and share these images of this wonderful and unique piece of history in Laser Technology.

Over the years I have been fortunate to have been given some old / ex medical lasers. Some of the major system included the Coherent system 900 series photocoagulator, 920 Dye and the 930 series argon Lasers.

I also acquired two Coherent Ultima 2000 On-demand argon laser units one for parts and one which is still operational.

I also have a number of ND-YAG cavities from the Coherent 7900 series YAG lasers.

It's not very common to come across as a surplus unit, however I was fortunate enough to be able to acquire a Copper Bromide II laser that was being sold off and then later another unit was saved from being thrown away.

The lasers are an Australian manufactured unit by Norseld in South Australia for the cosmetic and medical industry.

The laser tube is also made in Australia by a glass blower, Jess Fisher whom meticulously makes them from quartz glass.

The power supply for this laser is of the older variety using a hydrogen thyratron to switch the high voltage at high frequency.

The laser tube features three vertical extensions in which hold the Copper Bromide II material and are held inside a heated pot.

The tube is filled with neon buffer gas, when powered, the heaters are activated to begin the heating process. After around 10-min, the high-voltage will fire, causing the tube to discharge in the typical neon glow. The discharge will continue to heat the tube, as the copper vapour pressure continues to rise, the tube begins to lase.

The laser outputs two distinct wavelengths at 578.2nm (Yellow) and 510.6nm (Green).

Power output is around 8 Watts, with a power distribution of 2.5W yellow and 5.5W green and is a pulsed output at around 16kHz with a pulse width of 30ns.

The output windows are quartz, with a slight angle to prevent reflection back which would affect lasing due to the operational physics of a Copper Vapour system.

Legacy Archive:

Copper Bromide Laser

Read about my collection of Vintage Spectra-Physics Helium-Neon Lasers

- Flavio Spedalieri -

Written: 13th November 2020

Updated: 9th June 2025

This Document Complies to W3C

XHTML 1.0 Strict Standards