The Coffee Workshop

Over the course of the past 18 years, I have been fortunate to have been able to immerse deeply into the realm of the coffee industry, from learning the basics, through to shear appreciation from both the enjoyment of finding a memorable coffee, the shared friendships and technical knowledge and experience that I have built up over this time.

When I first began this journey, I was filled with an overwhelming sense fascination to the precision and at times, complexity on the side of the technology for the simplicity of making a beverage to be enjoyed. Not withstanding however, growing with Italian heritage, the trusted 'Bialetti' always had its place on the stovetop. Ironically, as a young boy, I have to say, I was not a fan of the taste of coffee, yet we reminisce on the past and appreciation goes beyond the colloquial term "Coffee Snobb".

There are certainly some interesting terms to describe one who undertakes a holistic approach to coffee, such as 'Javaphile', 'Coffee Afficionado', 'Coffeeholic' and 'Coffee Connoisseur' to name a few, however for me, I appreciate all things coffee from the artistic and creative elements that includes, beautiful espresso machines, the engineering aspects and the history of coffee and understanding of coffee agriculture, processing, roasting and development through to producing a coffee for others to enjoy.

It's without saying, my passions and interests in Science, Technology and Engineering and that when we think about it, the coffee industry is a melting pot of science, technology and engineering itself, any coincidence? Let's also consider the creative side in coffee, we now begin to enter the realms of the arts and photography... well you can see where that's going.

Having covered some substantial ground in the other sections on coffee, from my Coffee Grinder project, my roasting Journey and also covering the innovative 9Barista, It would not be complete not to have a small section on the technical aspects of coffee. Therefore, in this section I will begin with some basics and overtime endeavour to add to this resource.

Having worked in the coffee industry as a service technician as well as providing consulting services on all things coffee, there is one thing that constantly does not cease to amaze me.

Coffee brewing systems come in all forms, shapes, sizes, and prices. Focusing on the high-end domestic and commercial espresso machines, one of the first things that gets my attention in any café, is the cleanliness of their coffee machine, grinder and coffee preparation area is, this immediately communicates the care and passion or lack thereof one has when comes to coffee.

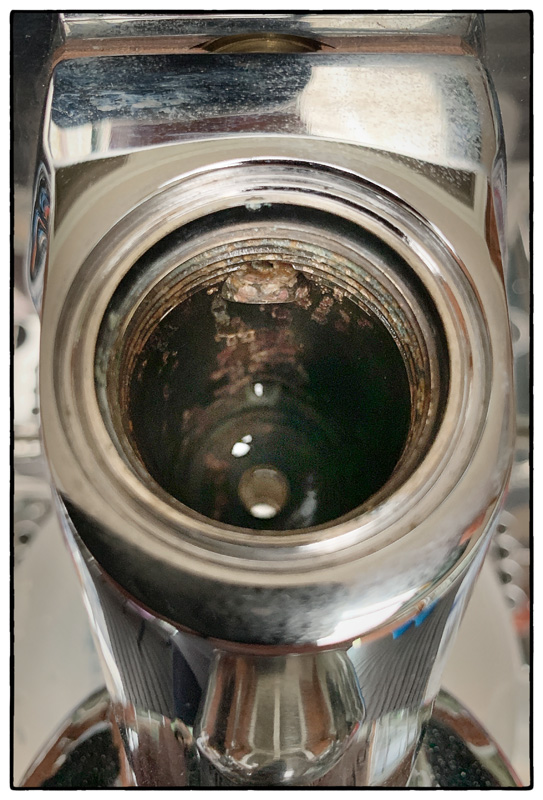

When a machine arrives in for a service, the first things that are noted, the conditions of the steam wands and group(s), and how clean the machine is overall.

I am constantly mesmerised when I see a machine arrive for service with a steam wand covered with cooked-on milk residue, and on removing the shower screen, it being completely blocked with rancid coffee build-up that has an appearance and consistency of 'Vegemite', Sadly its also these clients that ask why their coffee tastes bad, or that the machine does not make good coffee.

When the machine is put on the bench for servicing, and the boiler water is examined, and we find the water coming out of the boiler is so cloudy, and full of limescale, this is yet another telltale sign that there is no TLC taken, for me this is perhaps one of the most significant frustrations of all, a dirty Machine. Let's not open the can of worms when comes to grinders.

We must keep in mind one very critical piece of information, Coffee is a food product, and as such, cleanliness, hygiene and food safety protocols must be observed and at the forefront of working with coffee, it is paramount that coffee equipment is well maintained and regularly cleaned and serviced. A steam wand covered in baked on milk is a safety and biological hazard which can promote bacteria resulting in possible food safety concerns especially in commercial settings.

Coffee oils are deposited on areas in contact with brewing coffee, over a short time, these oils will become rancid and will taint the final product, if the machine is not regularly cleaned. This is also reason for regular 'backflushing' and chemical cleaning of a machine's group(s).

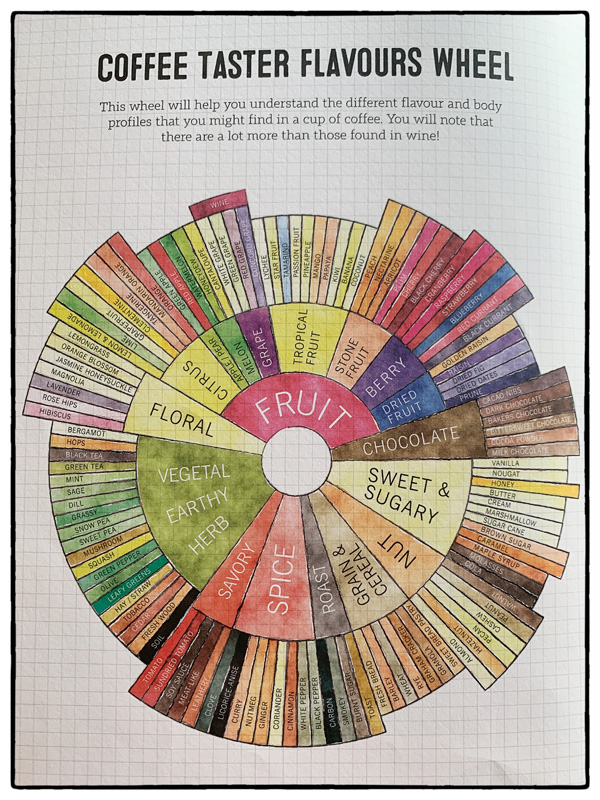

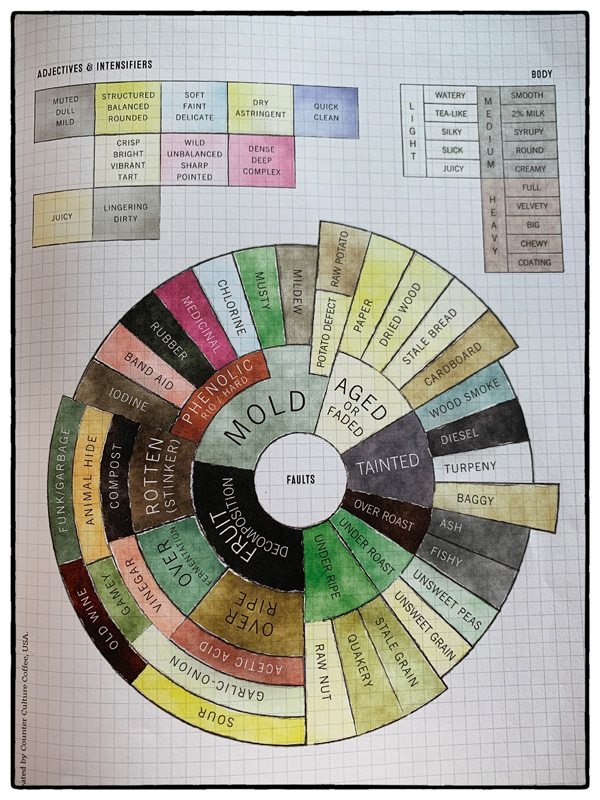

For the delicate notes and aromas locked in coffee, this starts with the coffee tree itself, the species of coffee, the origin of the farm(s) and countries, the growing conditions, altitude and additional crops (such as fruits and citrus) that grow around the coffee tree all play a vital role in determining the characteristics of a particular coffee.

The processing of the green raw coffee also is a very important characteristic that adds overall, however it is in the roasting process where the artisan's skill, knowledge and experience all come into play on unlocking the flavours and aromas of the coffee.

Immediately following roasting, coffee needs to rest to allow for it to stabilise and mature, and its also where in the first 24 hours after roast, the maximum release of Carbon Dioxide Gas occurs. When coffee is 'too fresh', this will lead to inconsistent extraction, and a significant and short lived 'crema'.

The optimal time to enjoy coffee at is peak is from around 1 week and upto 4 weeks post roast. Some coffee may stretch out to 6 weeks before losing its characteristics and becoming state. Roasted coffee may be stored in the freezer in an air locked bag (or unopened coffee bag with one-way release valve), and will be good upto 6 months after roasting.

The group head is a critical component of an espresso machine, where the culmination of a magnitude of variables come together to produce a product that we all know and love, coffee, (well in this case, espresso coffee).

From the group head, brew water is dispensed from a brew boiler or heat-exchange circuit and forced under pressure through a tamped bed of finely ground coffee that is held in a 'Portafilter' basket and extracted into a cup.

The term 'Group Head' has its origins and significance in the beginnings of expresso culture in Italy, where a number of machines introduced in café's consisted of multiple 'stations', each independently operated by the 'Barista' or Baristas to increase efficiency and allow multiple espressos to be prepared simultaneously.

There are many varieties and types of group heads, however the most common found on espresso coffee machines are:

- Manual Lever group - A completely manual machine without pump, the pressure is developed by a piston under spring tension, and the actions of the operator / Barista,

- Saturated Group ('Gruppo Saturato') - Invented by La Marzocco in the 1970s, essentially integrating the group with the brew boiler, to improve temperature stability and improved extractions.

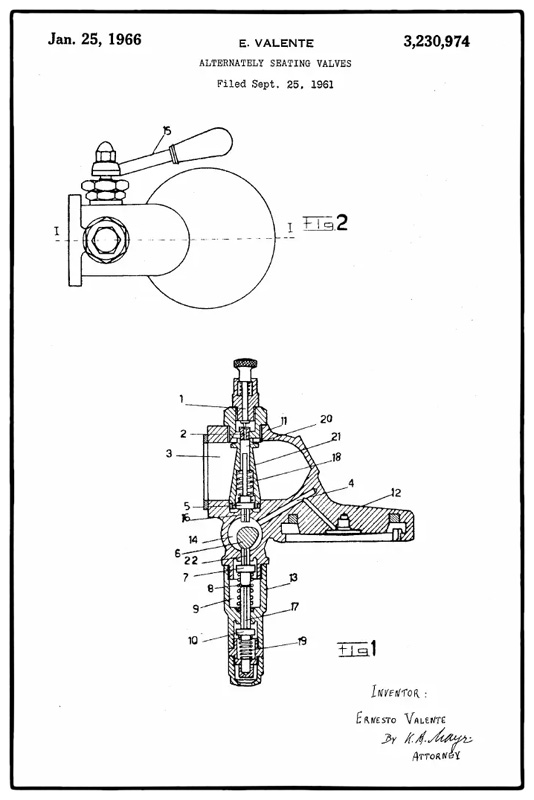

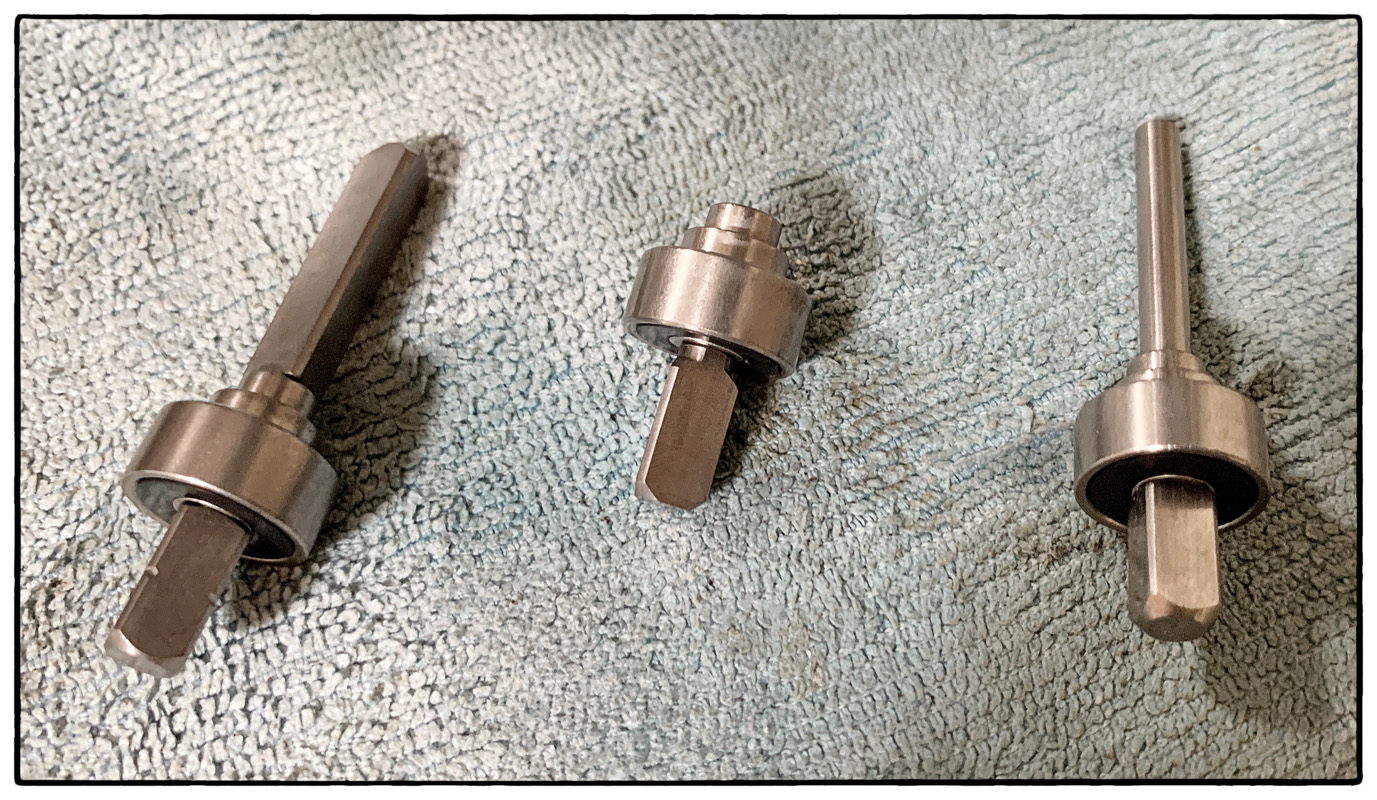

The Saturated group has been adopted by a number of other manufacturers including Synesso, Slayer and Kees Van Der Westen (KvDW) , - E61 Group Head - Invented by the Italian, Carlo Ernesto Valente, founder of 'FAEMA' in Milano, and introduced on the Legendary 'Faema E61' espresso machine so named for the Solar Eclipse of 1961.

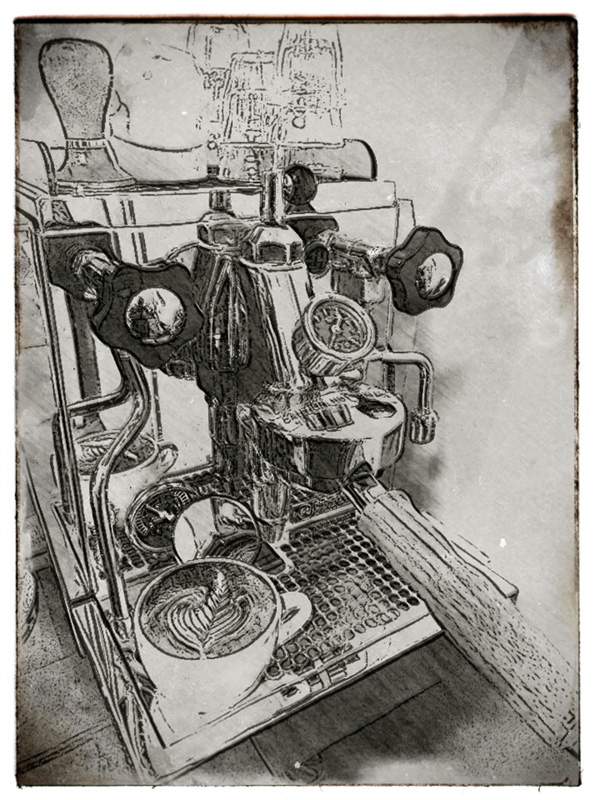

The E61 Group head is perhaps one of the more iconic and recognisable group heads used on espresso machines, and this is no exception that it has become one of the most common heads featured on high-end domestic / home espresso machines.

The Original E61 has many variations and designs including Electric Valve operated which replaces the traditional Cam-Lever operation.

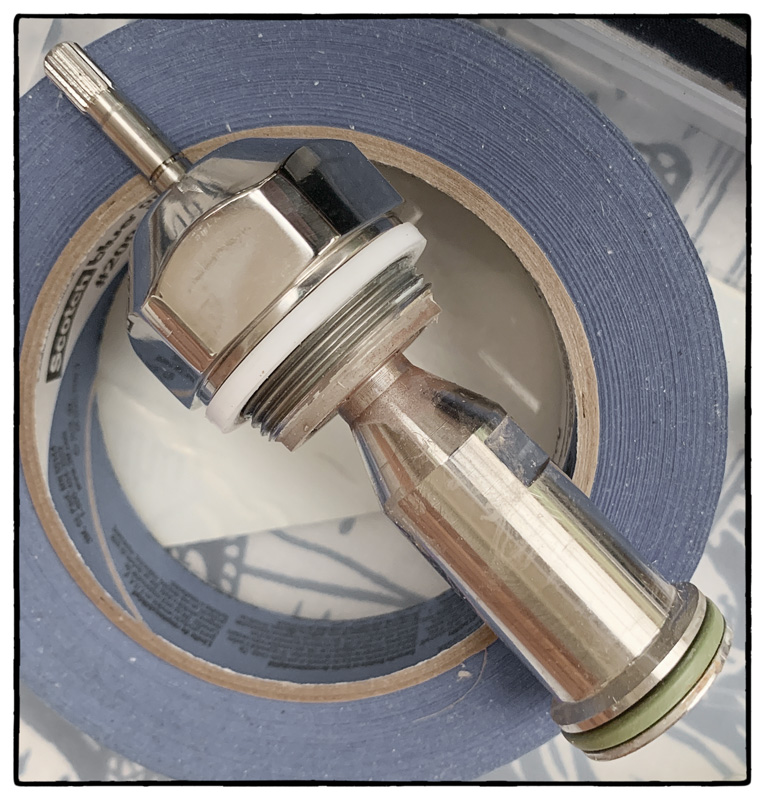

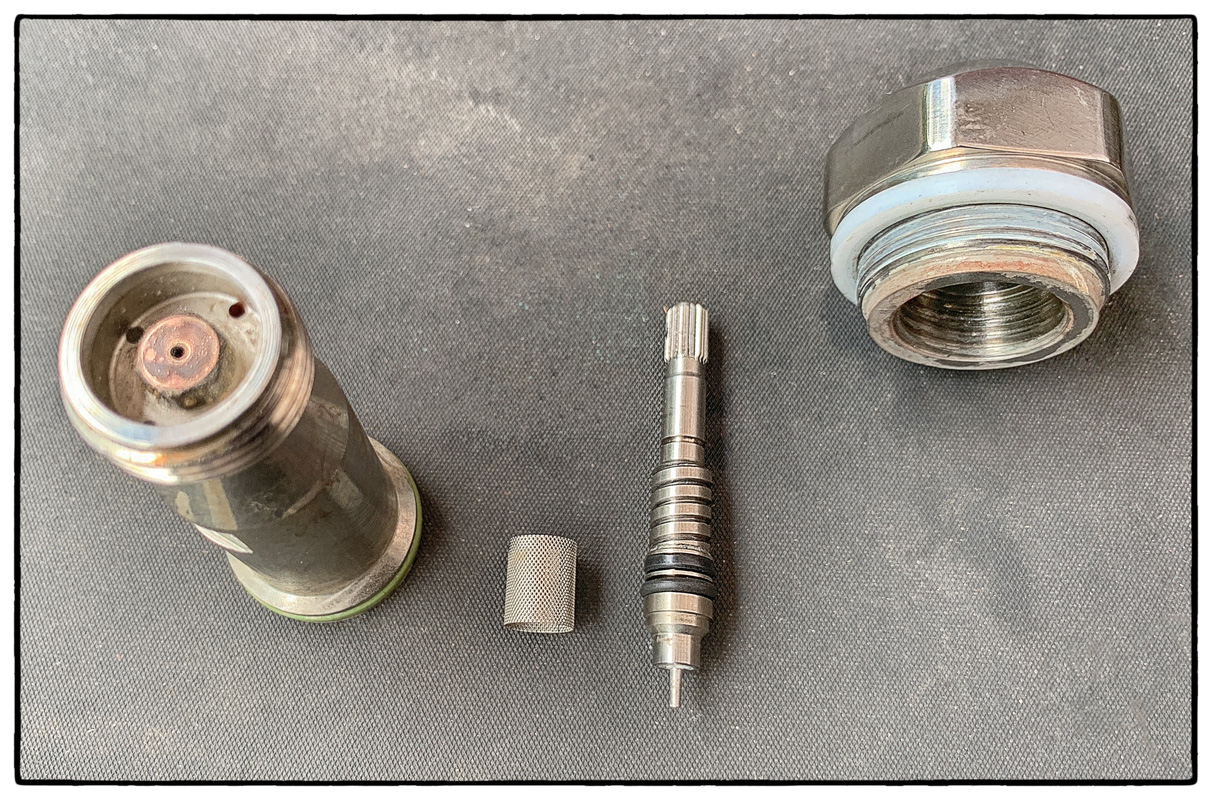

Another variation and one that is a feature of my fine-art image below, is the E61 ground found on the ECM Michelangelo. In this design, in-place of the three valve sets and Cam in the lower section (or stem) of the group, is a large spring-loaded piston, or Pre-infusion piston that sits inside the lower chamber to replicate the behaviour of a manual Lever. The downside of this design is the need for more regular maintenance to avoid the chamber becoming choaked with residue. This similar feature is found on Slayer and Kees Van Der Westen machines, however the pre-infusion piston / chamber is physically separate.

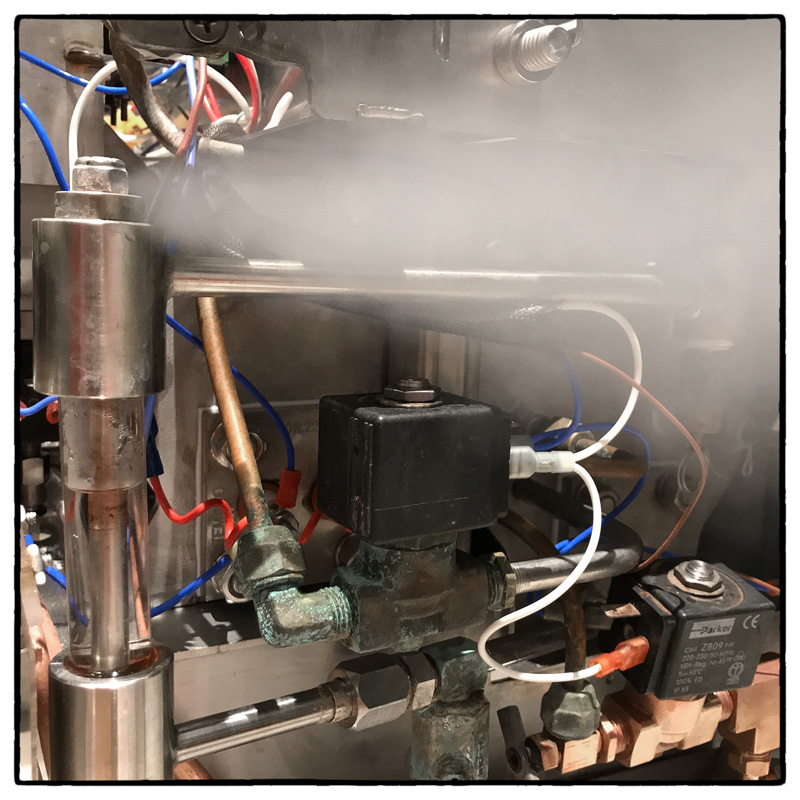

Let's explore some of the common topics and areas involved with working on espresso machines. Some of the most common issues involve leaks, machines not heating and or tripping

Some of the most common issues involve leaks, machines not heating and or tripping circuit breakers, and generally lack of regular maintenance including regular backflushing. It's always recommended to refresh water in the main steam boiler on regular basis.

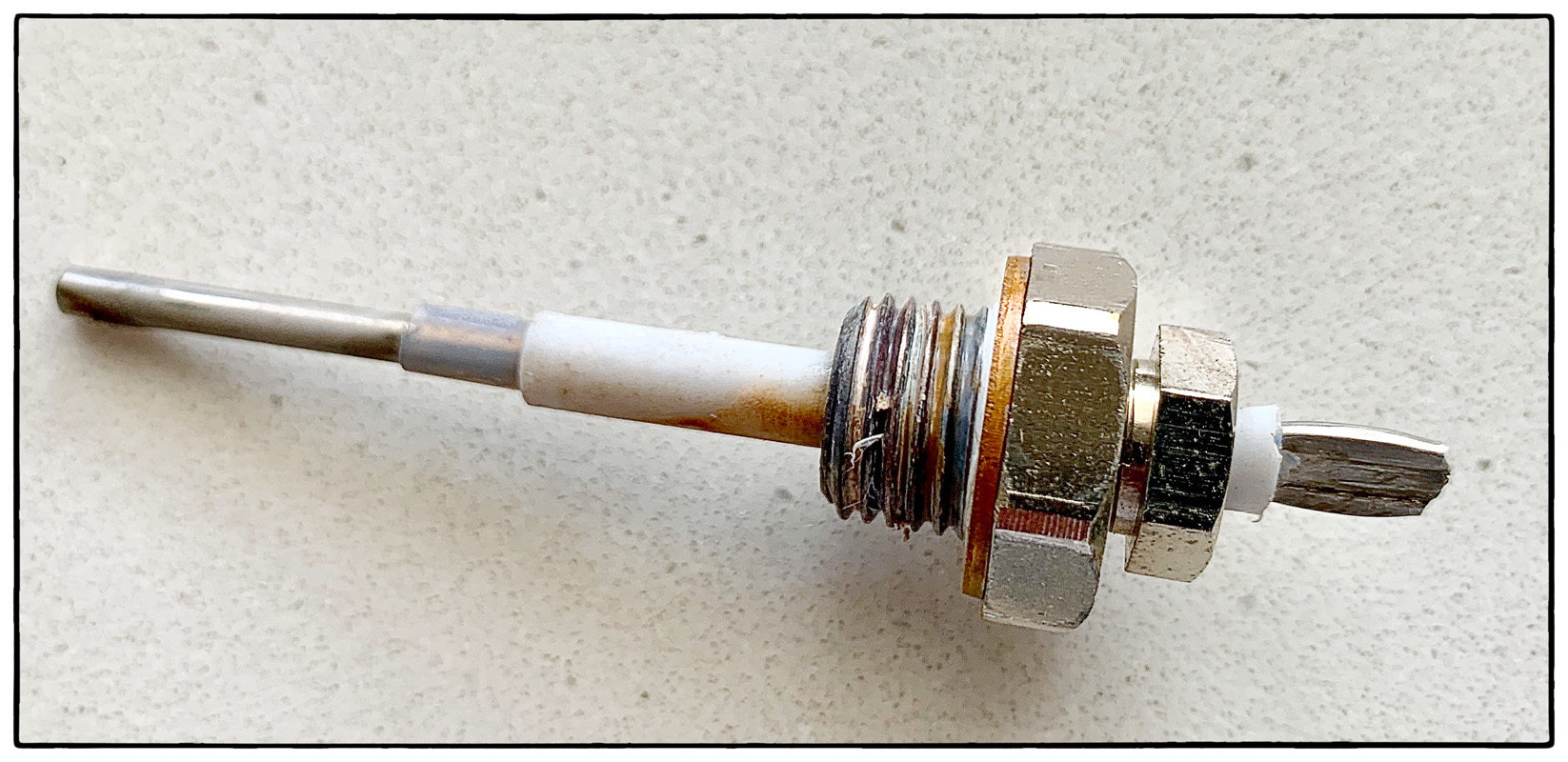

A clue to the quality of the water inside the steam boiler can be assessed by dispensing water from the hot water tap into a glass and observing for clarity, if there is any debris, or there is any tainted smell. We can further check this when a machine is on the bench and we remove the water level probe as well as the E61 'Mushroom'.

We still want the minerals contained in the water as this serves two important points, first is the taste and quality, and second, we need electrical conductivity of the water for the machine's water level detection circuit to function property.

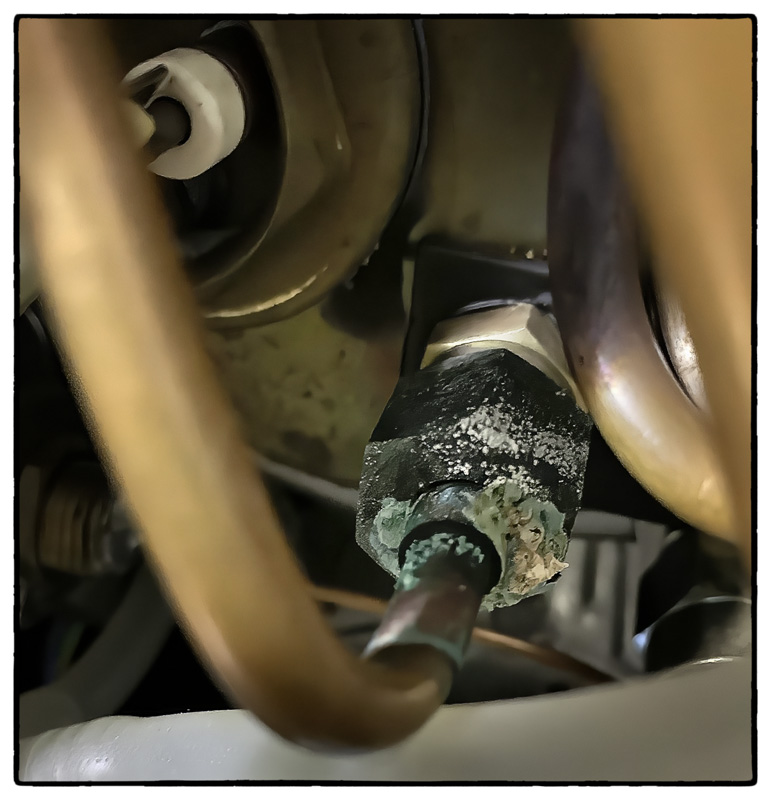

Signs of scale build-up and leaking hydraulic fittings. Its always good to address compromised fittings, especially ones connected to the boiler such as the Hot Water outlet. If a fitting corrodes and reaches a point where it breaks inside of the boiler, this will effectively write-off the boiler.

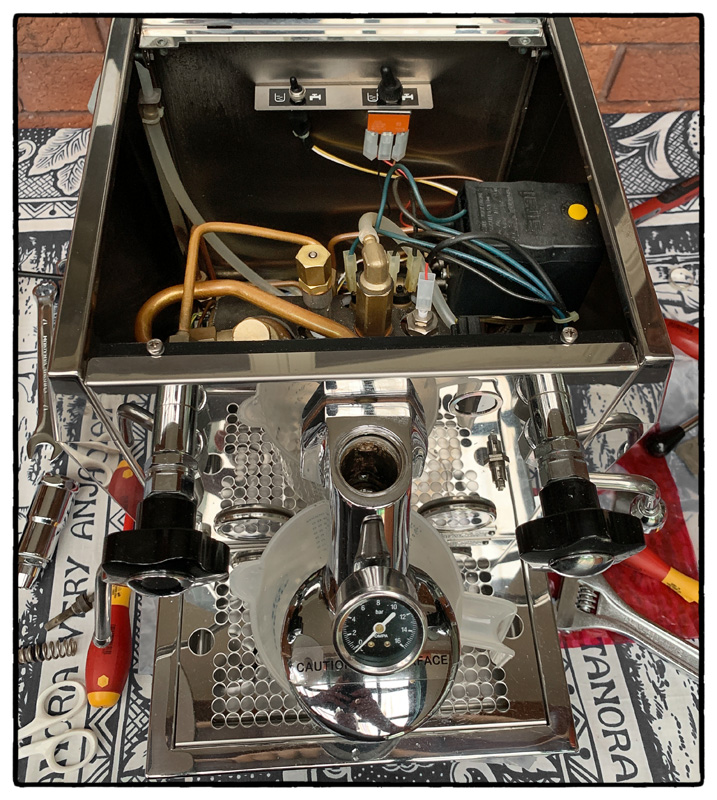

I regularly undertake maintenance and small improvements and modifications to my Giotto Evoluzione V2, this also allows me to address any issues and potentially compromised fittings.

Espresso Company Australia is just up the road from me, making it very simple to get parts when needed.

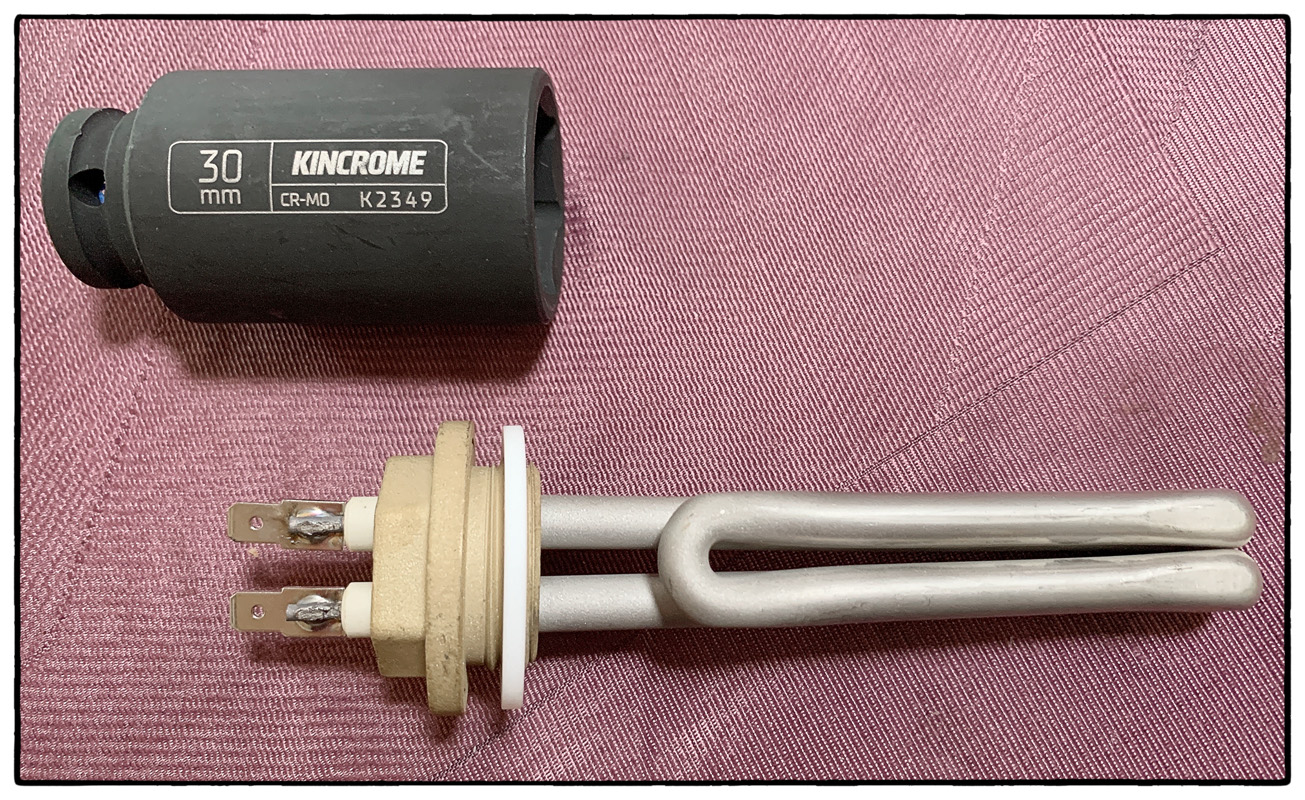

Returning to the topic of descaling, I have come across very ill-advised methods to introduce descaling solutions via the cold-water circuit, under no circumstances is this correct and further, should never been completed by heating the machine up to bring the solution into the boiler (via the cold circuit) - it's a fast method can also damage the element. The element should be removed when correctly descaling a machine.

The descaling solution is a mild corrosive, typically comprising of citric acid and lactic acid. These acidic compounds react with the calcium and magnesium carbonate compounds that form limescale in coffee machines, dissolving the deposits and removing them from the machine's internal components. Proper descaling procedure is an advanced service task that requires time to complete property. This involves removing components off the machine and separately soaking the parts in a tub. If the boiler requires clearing and descaling, it can also be removed from the machine and properly cleaned.

Typically, parts can be left soaking from minutes to overnight depending on how bad scale build up is. All parts will need to be thoroughly rinsed to remove all traces of the descaling solution.

From my own experience, a machine that runs all the time has less issues with scale, as limescale come out of solution and solidifies during cool-down phases. As previously mentioned, mitigating limescale is using correctly filtered water as well as regularly turning water over in the steam boiler.

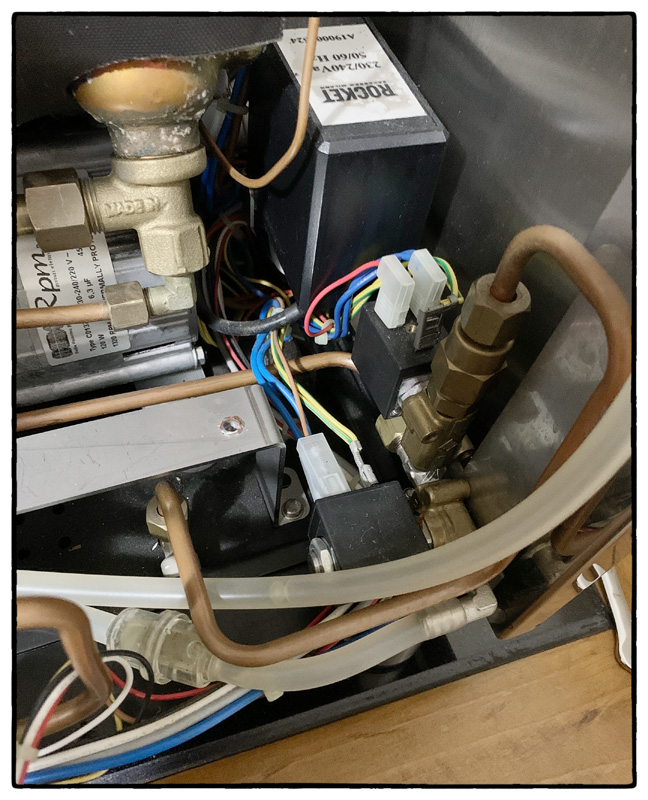

Rocket Giotto on Bench

Rocket Giotto Evoluzione V2

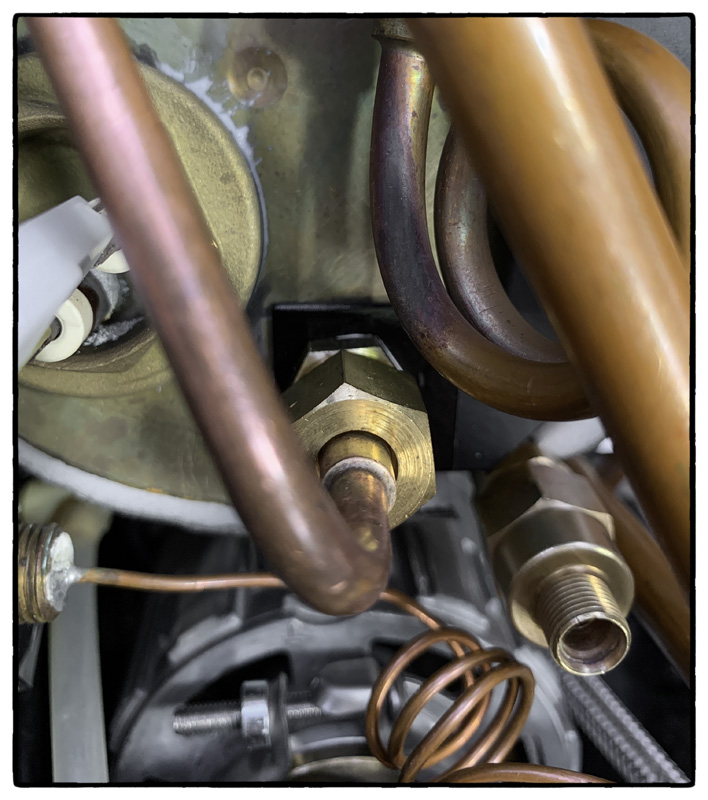

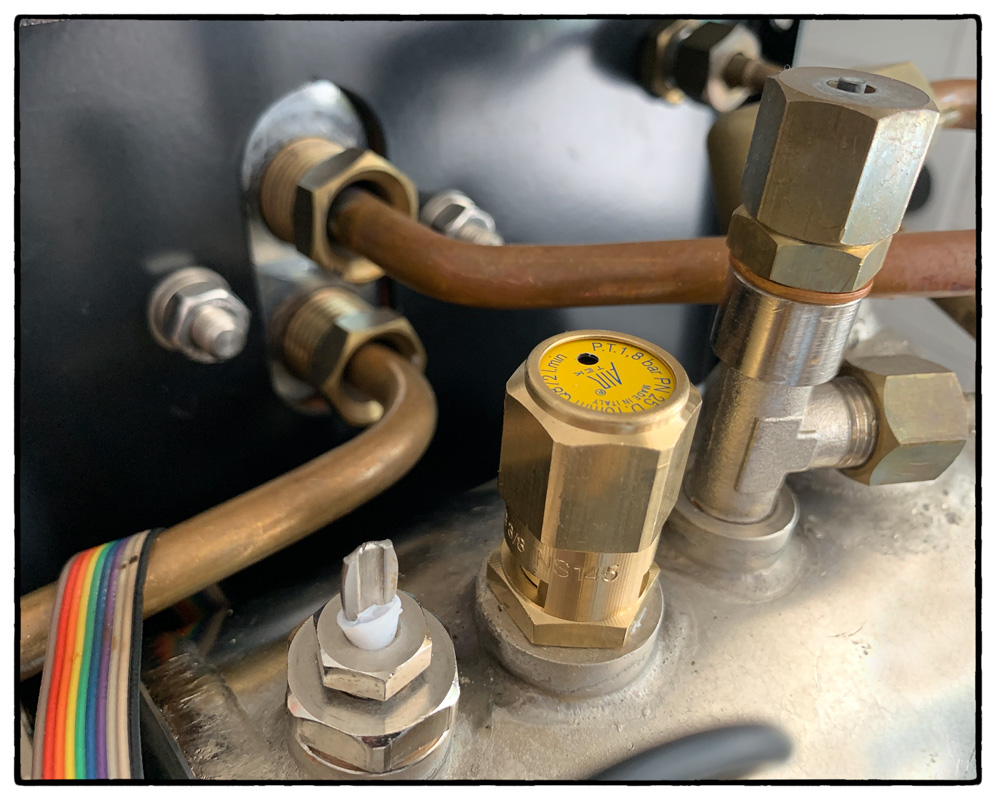

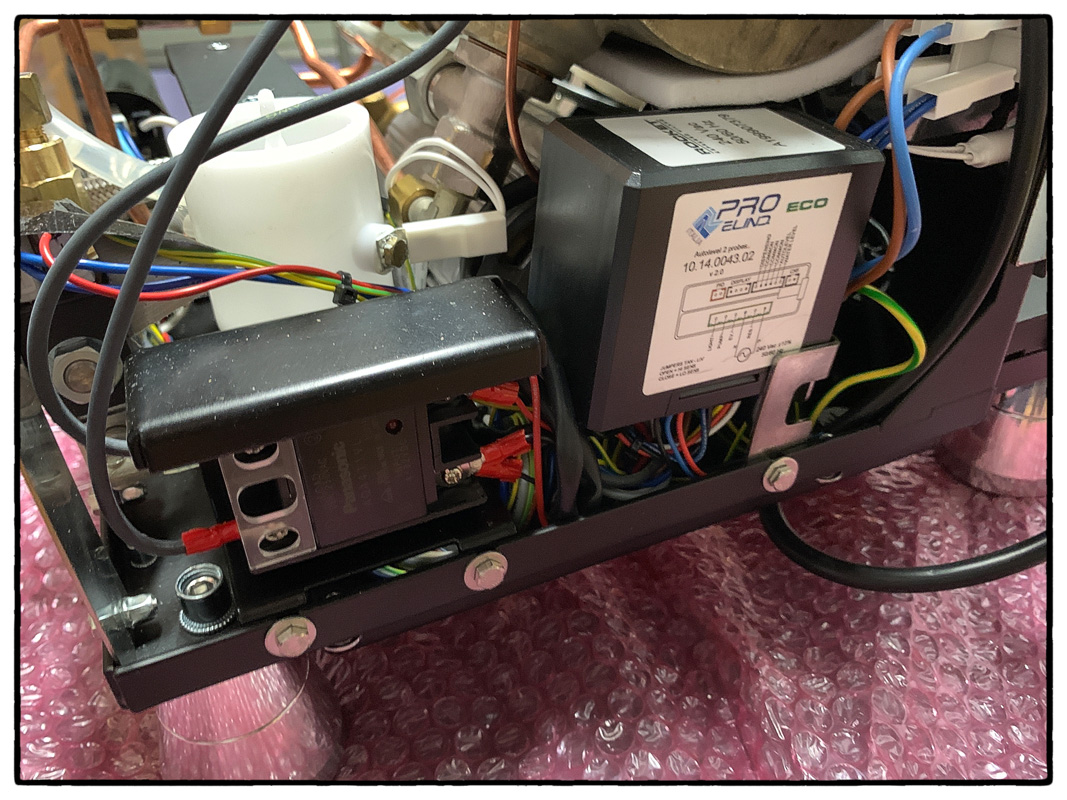

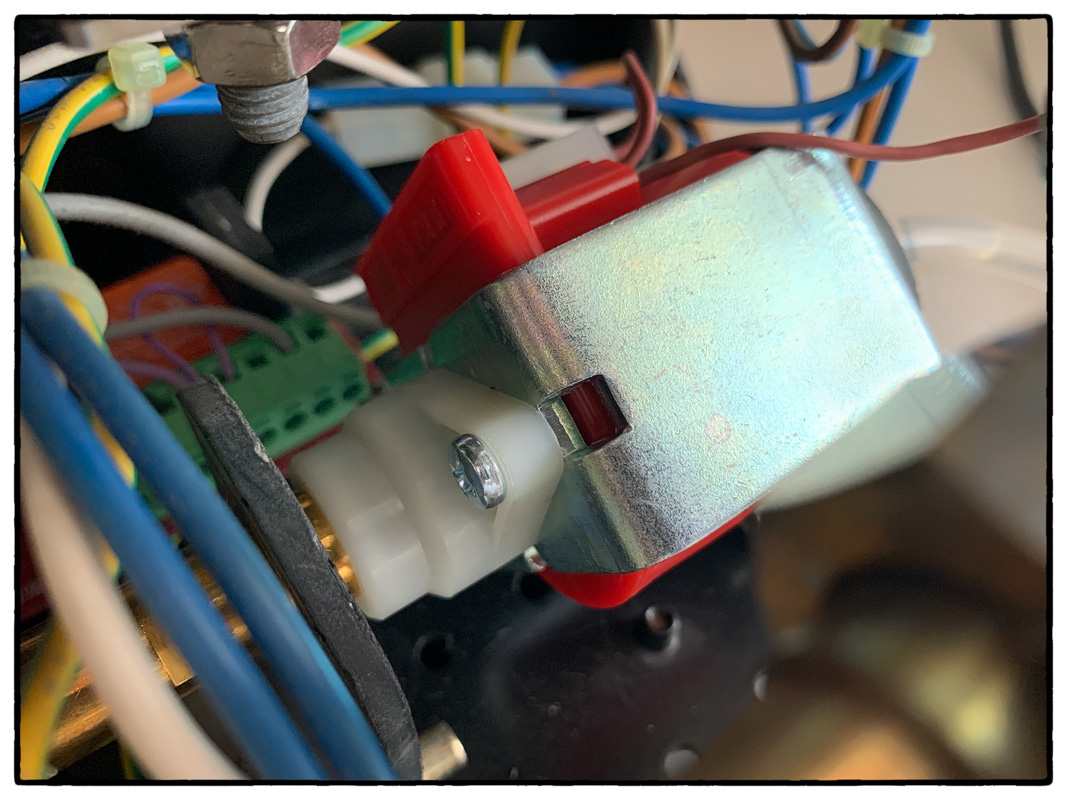

The Main boiler has several fittings, and also depending on configuration, however all will have a water level probe used to signal to the controller when need to fill the boiler, the Over-Pressure Valve (OPV) is a safety device that is set to let off pressure, typically set at 1.8 bar. In this image below, I fitted a certified OPV.

The final device is an anti-vacuum valve this is used to effectively open the boiler to atmosphere when its cold and closes when pressure has sufficiently built, this prevents false pressure reading of the main pressure stat that controls the element.

Note: Depending on the machine type, a PID controller can be used in place of a pressure stat, this allows for much finer control and temperature setting of a machine.

Level Probe, OPV Safety Valve, Anti-Vacuum

E61 Upper (Preinfusion) Chamber

One of the upgrades or modifications I have adapted to my Giotto is the Profitec Flow Control. This allows to control the flow at the group allowing to profile a coffee.

This can be a useful addition, however not necessary.

Key components in a machine include the main control unit, an electronic module that controls boiler fill, water level detection, and other machine parameters. Some can also combine shot timers and PID controls.

The main pump is either a Vibration style of pump or a rotary vane pump. Rotary pumps deliver a consistent flow and are less noisy.

As part of the service toolkit, is the group manometer, allowing to adjust the machine for correct pressure at the group.

Temperature control is achieved by adjusting the Steam boiler pressure and or the PID of the machine is equipped with PID Controller.

Perhaps one of the most understated key factors in brewing an excellent and memorable coffee is that of the humbled grinder, a piece of equipment that sits trustingly alongside the workhorse that is the espresso coffee machine, however it's role, seems all but just to grind the coffee, however this is far from the story. - Let's grind deeper into this rabbit hole. . . but not to fine, otherwise we crack under pressure.

After all of the many variables that comes with coffee and trying to obtain a sublime experience, the process to grind coffee into finer particles to increase surface area to achieve high-extraction yields is perhaps more important over all that the actual coffee machine.

In fact, one can make an excellent coffee to rival an expensive and high-end espresso machine if you have the right grinder, I have a 9Barista and Aeropress to prove this.

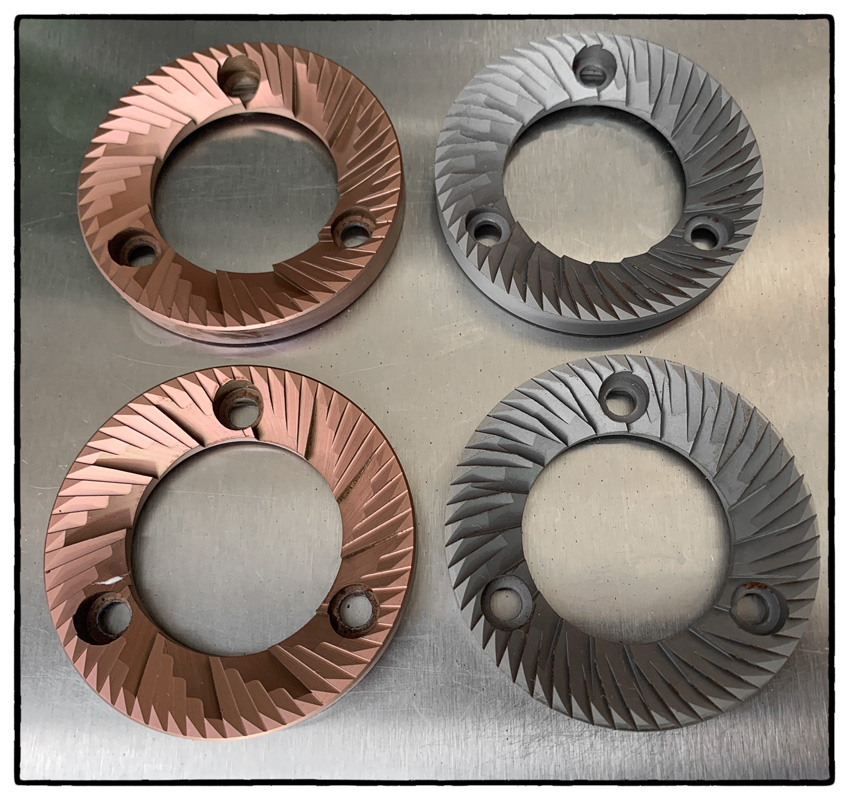

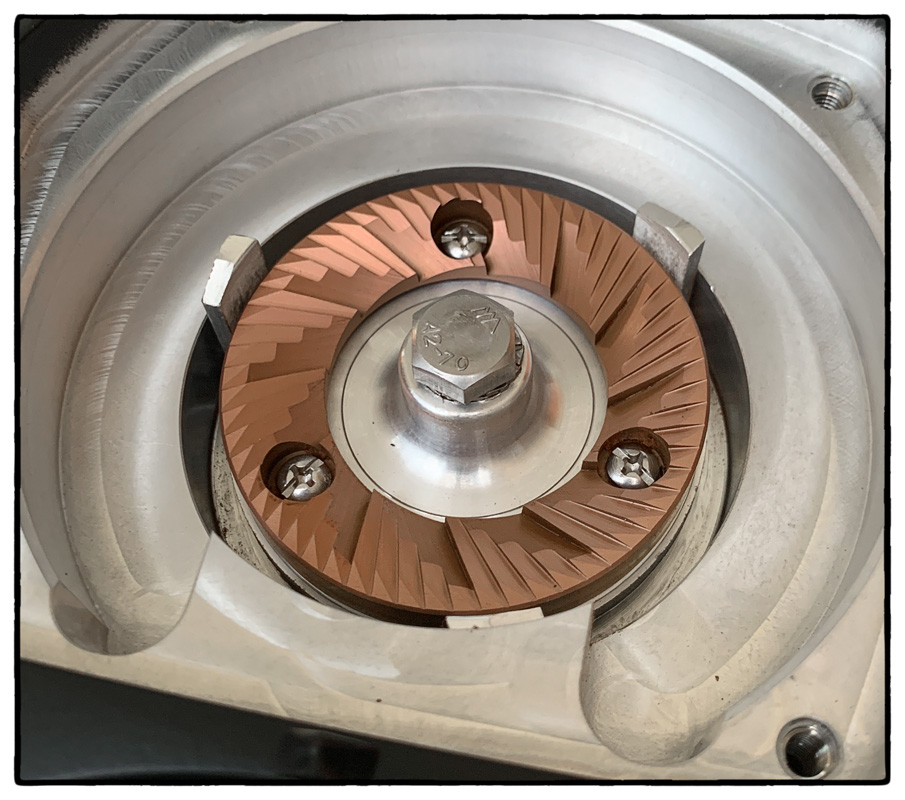

In our modern coffee industry, focus has shifted towards the grinder, in particular the grinding burrs and the geometry and size of the burrs to deliver different grind-size distributions for different brewing methods to optimise the extraction yield a percentage value of the TDS (Total Dissolved Solids) of an extracted coffee.

The market has been privileged to have a large selection of high-end quality grinders, from hand grinders through to units costing many of thousands of dollars. One such grinder, is the Titus Grinder by Frank Durra who was inspired by the VersaLab grinder, however, completely re-engineered from the ground up.

One of the number one Burr manufacturers of resent times, are S.S.P, focusing on all these variables and developing a range of burrs to suit the demands of the coffee industry.

64mm Flat Burrs, S.S.P (Left) vs Mazzer (Right)

In 20202 I embarked on a substantial project on converting a Compact K6 grinder, a substantial project taking place during the lockdowns of 2020. To read more about this journey, head on over to the

dedicated section on this Grinder Conversion project.

The significance of this project had it published in the

September 2023 issue of Silicon Chip Magazine,

an Australian Electronics publication.

One of the misconceptions is that the 9-Bars of pressure that is exerted on the bed of coffee is generated by the pump-drive machine, however this is not quite correct.

With fluid dynamics, pressure is a result of the Resistance multiplied by the Input Flow of the fluid. Without resistance, there is no pressure.

Pressure = Resistance (of bed of coffee) X Flow Rate of water from the machine.

To achieve this pressure, it is the fineness of the grind that will determine the overall pressure, that is, if the resistance of the coffee bed is low due to coarser gride, pressure will be lower, in contracts, if the grind is too fine, the pressure will climb to that of the machine's setting, which typically the over-pressure valve (OPV) or bypass on a rotary pump is set to 9-Bar using a group manometer to read pressure at the group.

I also own a Pesado TPD (Temperature and Pressure) device which as a small needle adjustment to replicate the flow through the bed of coffee, to more accurately set correct pressures.

For a machine with a Rotary pump, normally these have both an additional OPV for the thermosyphon circuit and the rotary pump head has a bypass adjustment, in this case, the thermosyphon bleed-off OPV is set to 12 Bar and the pump bypass set to 9-Bars at the group.

In September 2025, I assisted with a replacement of a failed element, when removed the element, it was surprising to see the failure mode. The element itself seems to have cracked open in a rather violent way, exploding the internals of the elements inner tube.

The result of this was the boiler becoming contaminated with the magnesium oxide powder, requiring flushing out the boiler.

Over the years I have meet many different people in the coffee industry and have been instrumental in shaping my own knowledge, experience and inspired me along my journey.

From a technical standpoint on coffee machines both domestic and commercial, and perhaps one of the very few with knowledge and experience as a service engineer, designer and manufacturer of parts, modules and features and that I have had the privilege to test out new hardware modules from Sean Alcorn of Alcorn Café Engineering who has made significant in-roads on manufacturing and developing superior parts for coffee machines here in Australia.

Installed into my Evoluzione 2 is the ACS DotShot as well as an improved controller board which Sean as expertly redesigned, ironing out the deficiencies in OEM parts, which is amongst a library of many other parts on offer. Installed on my former 2007 ECM Giotto, is Sean's Original ACS ShureShot timer which paved the way for new after-market modifications.

Amongst many resources available on the 'interwebs', some of the key resources which continue to drive knowledge and discussions including:

- James Hoffmann

- Lance Hendrick

- CoffeeSnobs

- Australian Specialty Coffee Association (ASCA)

- BeanScene Magazine

- Flavio Spedalieri -

Written: 30 September 2025

This Document Complies to W3C

XHTML 1.0 Strict Standards